The metal fabrication workshop has a lot of auxiliary machinery, so as to be able to fulfil a large number of our orders.

MEBUSA FOLDER

Force 120 T

Folding Length 3100 mm

Length fold between

uprights 2600 mm

Depth Swan Neck 400 mm

Work Speed 9 mm/sec

HYDRAULIC GUILLOTINE SHEAR

(MEBUSA) HCG-3112

Length 3450 mm

Width 2120 mm

Height 1810 mm

Nominal L. 3100 mm

Nominal Thickness 12 mm

Supplementary capacity 14 x 1500 mm /16 x 1300 mm

Cut Cadence /min 16 to 24

Cutting Angle Variation 0º 40´ to 1º51´ /Max. 2º41′

Swan Neck 500mm

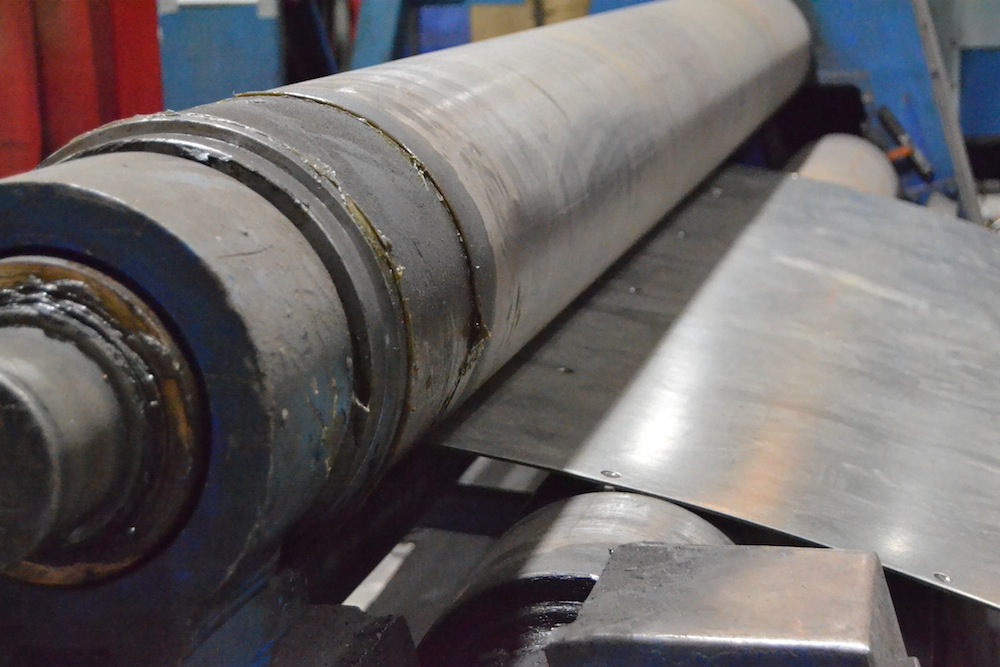

BIKO CYLINDER

Length 3050

Curved Thickness 16 mm

Pre curved Thickness 13 mm

Top roller diameter 275 mm

Lower roller diameter 250 mm

HYDRAULIC PRESS

Total effort 150 T

Effort Drawing 100 T

Effort Cushion 50 T

Maximum Pressure 210 Kg/cm2

Travel 650 mm

Working speed 16 mm/sec

ERCOLINA TOP BEN TUBE BENDER

Automatic Control of the hex shaft rotation during manufacture.

Speed 0.5 to 2.5 rpm

Max. Curvature angle 180º

Matrix 2″

Counter matrix 2″

Minimum diameter 5 mm

PUNCHING MACHINE GEKA

Flat bar shear 600 x 15 mm

Square B. shear 400 x 20 mm

Working Height 960 mm

L shear at 90º 160 x 160 x 16 mm

L shear at 45º 70 x 70 x 7mm

Round shear 50 mm

Square shear 50 mm

IPN shear 180 mm

Plate notching 13 mm

L notching 100 MM

Tube notching 60mm Diameter

Punching (Depth) 610 mm

Working height of 1165 mm

Max. Fold Length 700 x 3 mm

Max. Fold Capacity 400 x 10 mm

PROTEM US 150 PIPE BEVELLING MACHINE

- Solid and portable

- Can weld soft steels, stainless steels, duplex and super duplex steels, nickel-copper alloys, Inconel, P91, aluminium, copper and exotic alloys

- Diameters: from 150 mm (5,906″) int. to 508 mm (20″) OD

- Optional 610 mm (24″) tool holder

- Motorized or pneumatic, electric or hydraulic

- Up to four simultaneous machining operations

- Operations include bevelling at 30°, 37°30, 45°, with or without heel, J-bezels, compound chamfers, straightening operations, recess…

- Quick tool change and adjustment. Carbide inserts can be used